The Classic winding machine

Advantages

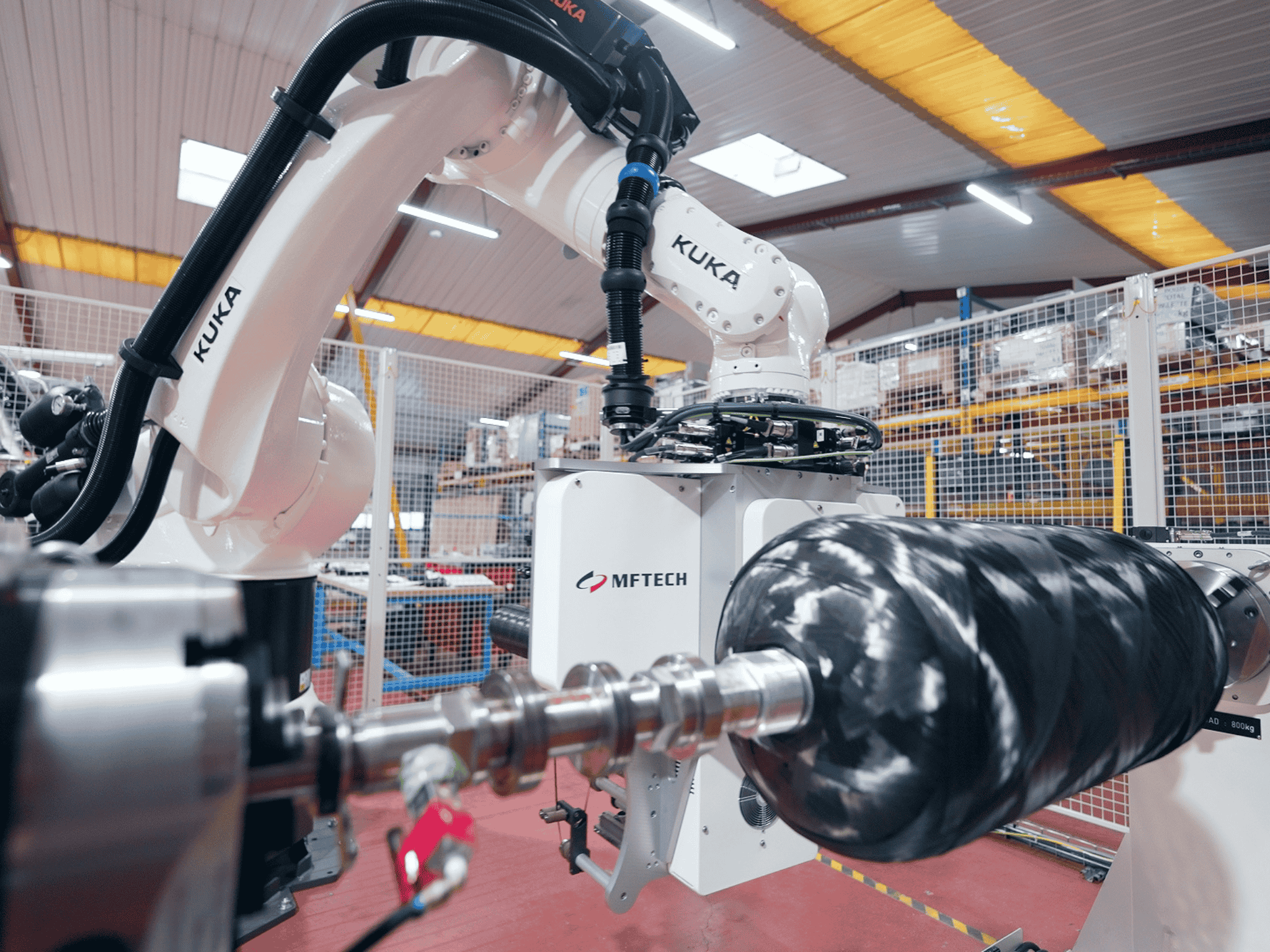

Classic winding machine

No size limit

Compact Design

Versatile material feeding

Applications

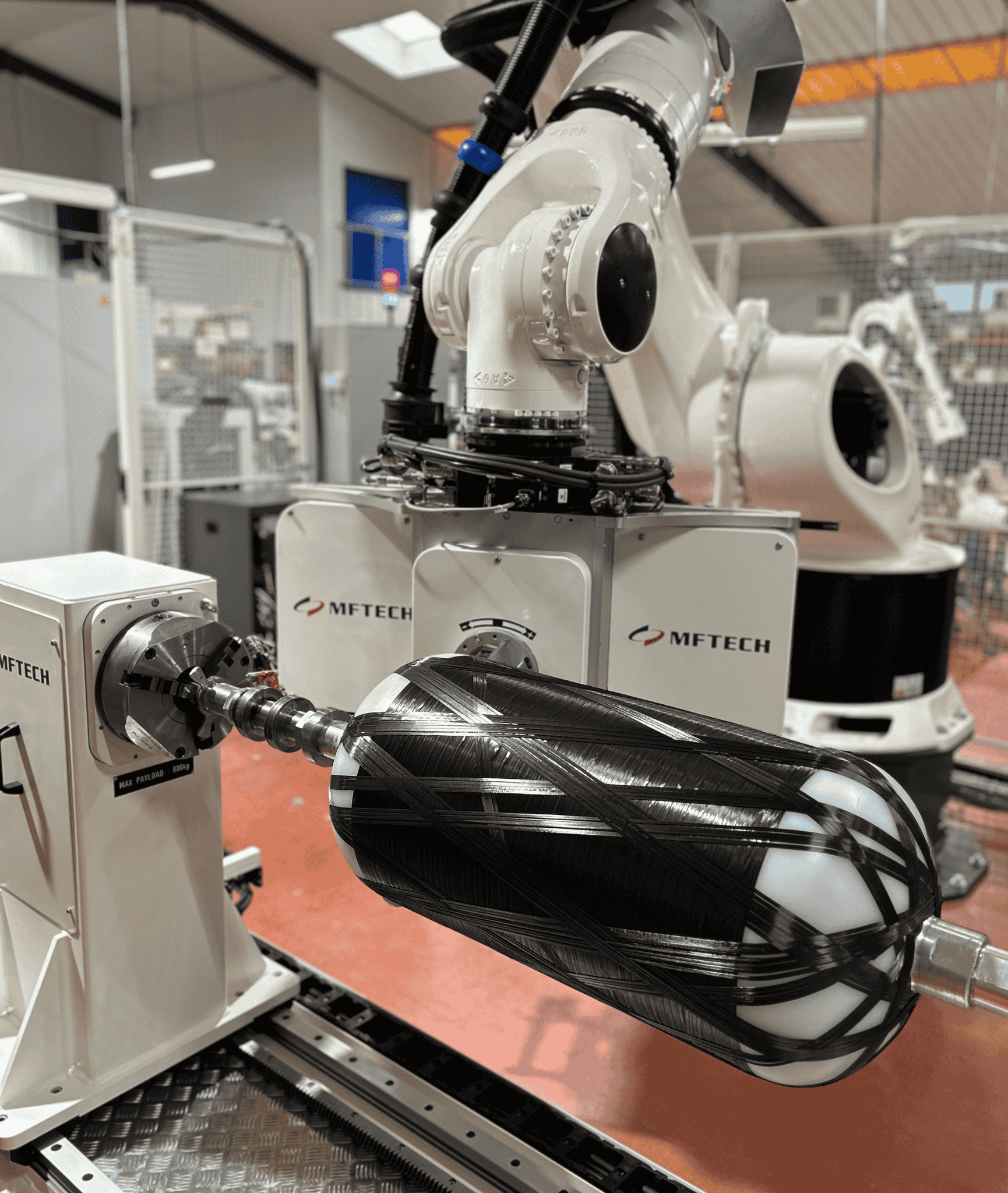

All composites vessels

From Type II to V

Tubes

Defense, Space, Leisure, Aircraft

Complexe shape

Thanks to the use of robot flexibility, various shapes can be studied by our experts

Technical informations

FW process specifications

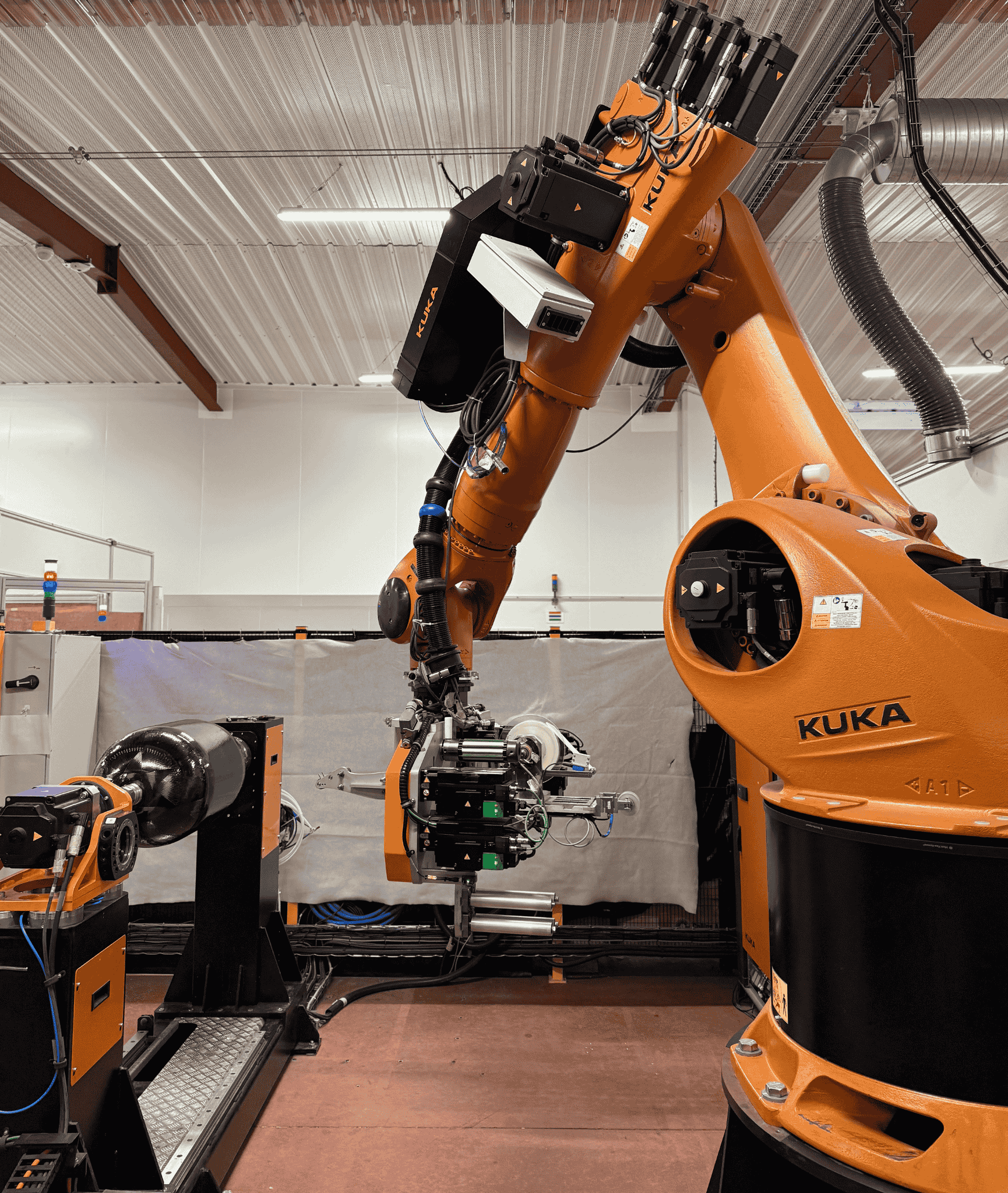

| Kuka robot | Delivery head managed by a precise and repeatible robot for optimized deposition |

| Fiber configuration | 1 to 24 spool Dry fiber Tow preg |

| Various tensioning configurations | Spools embedded on the head Tensioner on floor Tensioner embedded on the robot track |

| Tension | Mini : 20 N Maxi : 60 N |

| V max winding | 2.5 m/s |

| Preg & Wet configuration | Easy switch from preg to wet winding with the same machine |

| Spool loading | <2min |

| Head and feeding eyelet | <10 min |

| Precision | ±0.8 mm |

| Repeatibility | ±0.08 mm |

Positionner

| Max opening | 10 000 mm |

| Diameter max | 2 000 mm |

| Maximal weight | 800 kg (as standard, and more on request) |

| Maximal rotation speed | 187.5 tr/min (tuned for each need) |

| Pulling force | 2400 N |

| Tolerance | ±50 N |

Resin bath

| Maximal volum | 3L |

| Design | Easy cleaning |

| Heating system | Heating carpet or water flow circuit |

| Automatic filling | Compatible with various resin pumps brands |

Options

| Number of tows | More fiber available on request |

| Positionner | From 0,5T to 80T |

| Spindles | From 1 to 5 spindles |

| Time optimization | Various automatized robot tasks |

| Doctor blade | Manual and automatic |

| Pneumatic chucks | For exchangeable heads |

| Scada | Data acquisition for Industry 5.0 |

| Liner pressurization | Up to 10 bar |

| Overtension system | Up to 1000N |

Get in touch with MFTECH

Feel free to contact us to discuss your composite part automation project. We’re here to help you, every step of the way from the design until the manufacturing.

Rue Condorcet – Z.A. du Mourillon

F-56530 Quéven

Tél : +33 2 97 59 94 98

About us

Our offer

Follow us

© 2023 – Coriolis, made with ❤️ by Lamour du Web